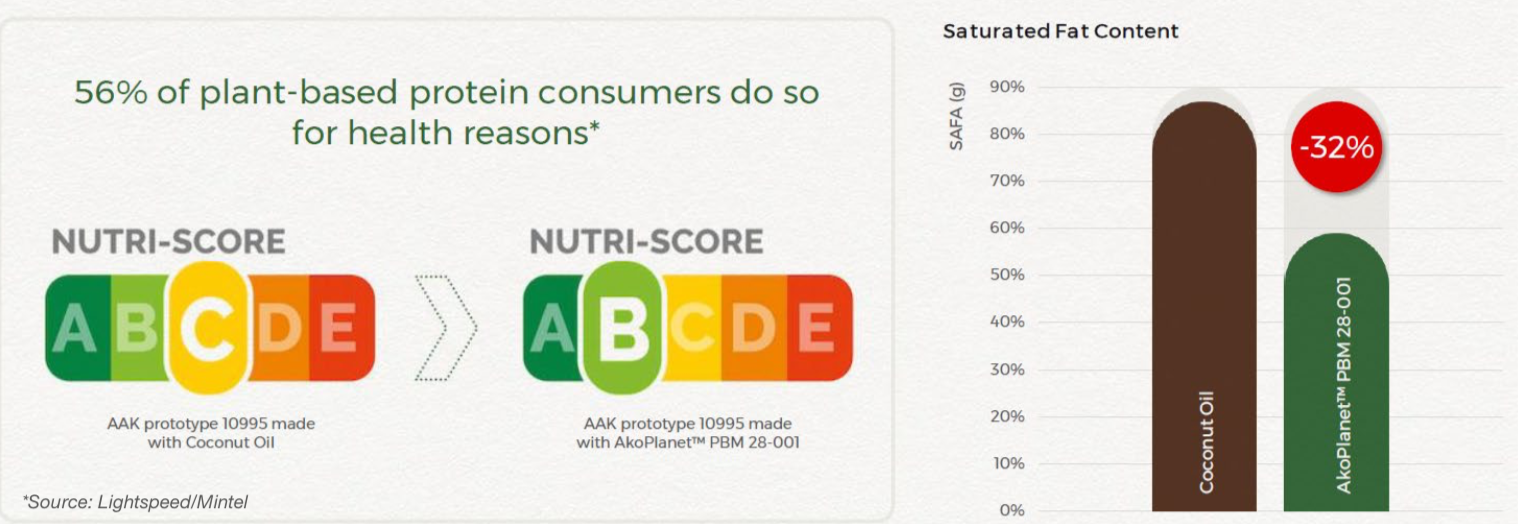

Made with AkoPlanet™ PBM 28-001 for a juicy plant-based burger with 32% less saturated fat than when made with Coconut oil.

The New Age of Meat Alternatives – Achieving the Right Marbling

One of the greatest challenges to achieve the perfect plant-based meat analogue is replicating the muscle like fibers which deliver the firm bite consumers expect from meat.

According to Melissa Machen of Cargill, “Marbling is the intramuscular fat between fibers in a muscle. Marbling offers consumers a more juicy and flavorful eating experience. Beef, for example, is graded based upon the amount of marbling. Vegetable oils like coconut oil and palm oil may be used to impart the “marbled state” in plant-based steak alternatives or plant-based burger alternatives.”

However, vegetable oils are liquid at room temperature, which makes it very challenging to achieve a marbled appearance in the product. To resolve this problem, oil can be blended with other ingredients like gums and starches at cold temperature resulting in a solid material that can be reduced in size to resemble small pieces of fat particles.

The fat particles can then be incorporated into a plant-based steak or burger at cold temperature to assume a marbled appearance. (There are also methods to achieve this using entirely clean label ingredients for plant-based meat applications.Please contact FSL to discuss.)

According to Vineet Jindal, PhD, Customer Innovation Manager at AAK, “Companies need to create a plant-based fat system that appears like conventional steak marbling, and they also need to incorporate and bind the fat system in plant-based “muscles”, so it appears like marbling in steak.”

“In addition, the marbling also needs to release the aroma of that particular meat during and after cooking,” he said. “The integrity and appearance of the product also needs to be maintained during and after cooking.”

To achieve this marbling effect, AAK have developed AkoPlanet PBM 28-001 – a fat flakes solution specifically designed to create marbling in plant-based meat applications and which stays solid at room temperature but melts at higher temperatures to release the juicy flavor of a burger.

This fat solution from AAK also reduces the total saturated fat of a plant-based burger when compared to other types of vegetable oils such as coconut oil.

Plant-based Burger Patty

Allergens: Samples are prepared in application laboratories where allergens may be present. Note this formulation contains protein from peas and fava beans. members of the legume family.

The information described above is offered solely for your consideration and independent verification. AAK makes no warranty about the accuracy or completeness of the information contained above or the suitability of any of their products for your specific intended use. Furthermore, all express or implied warranties of non-infringement, merchantability or fitness for a particular purpose are hereby disclaimed. All the information in this document remains the intellectual property of AAK.

Ingredients: Water, Textured Pea Protein, AkoPlanet™ PBM 28-001 (Shea Oil, Coconut Oil) (11.70%). Pea Protein Isolate, Textured Fava Bean Protein, Natural Flavour, Methylcellulose, Concentrates (Beetroot,Carrot,Spirulina,Paprika), Garlic Powder, Salt, Black Pepper.

Nutritional values

|

Typical values per 100g |

|

|

Energy |

861kJ / 207kCal |

|

Fat |

13.0g |

|

of which Saturates |

7.1g |

|

Carbohydrates |

6.4g |

|

of which Sugars |

0.8g |

|

Protein |

15.4g |

|

Salt |

0.3g |

Plant-based Burger Patty

By switching to AkoPlanet™ PBM 28-001 It’s possible to make a healthier burger with less saturated fat, In this recipe moving from Nutri-Score C to B.

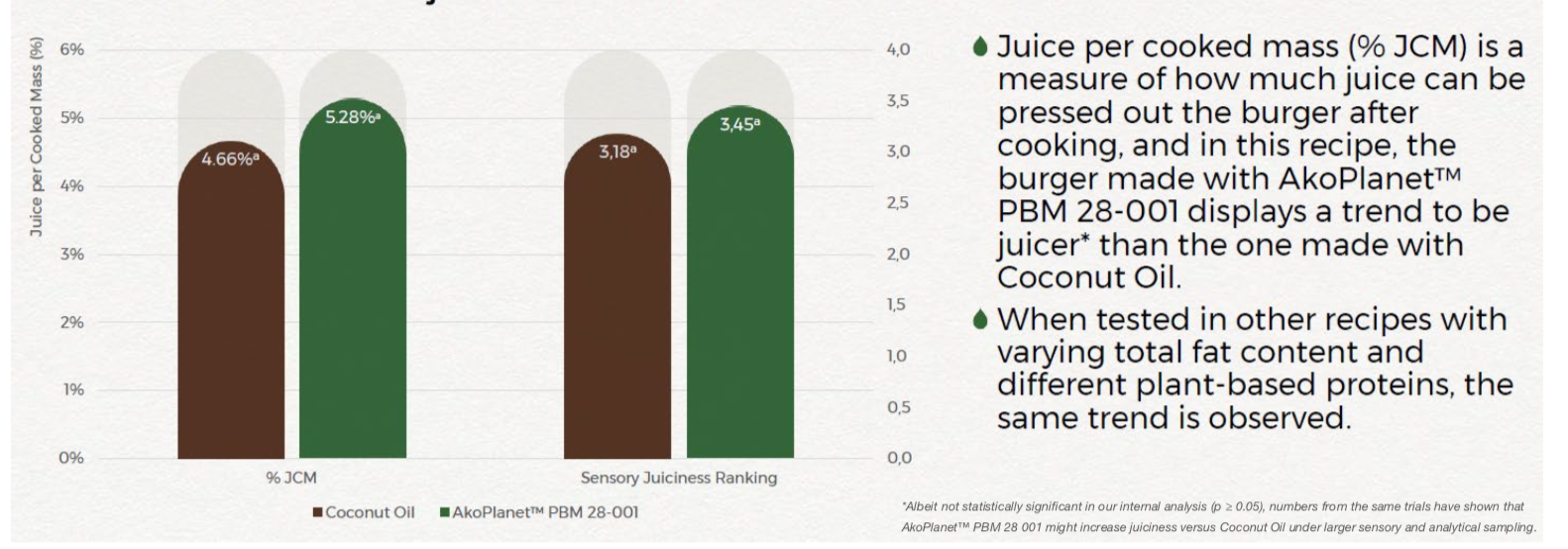

Besides being significantly lower in saturated fat, burgers made with AkoPlanet™ PBM 28-001 tend to be juicier than those made with Coconut Oil.

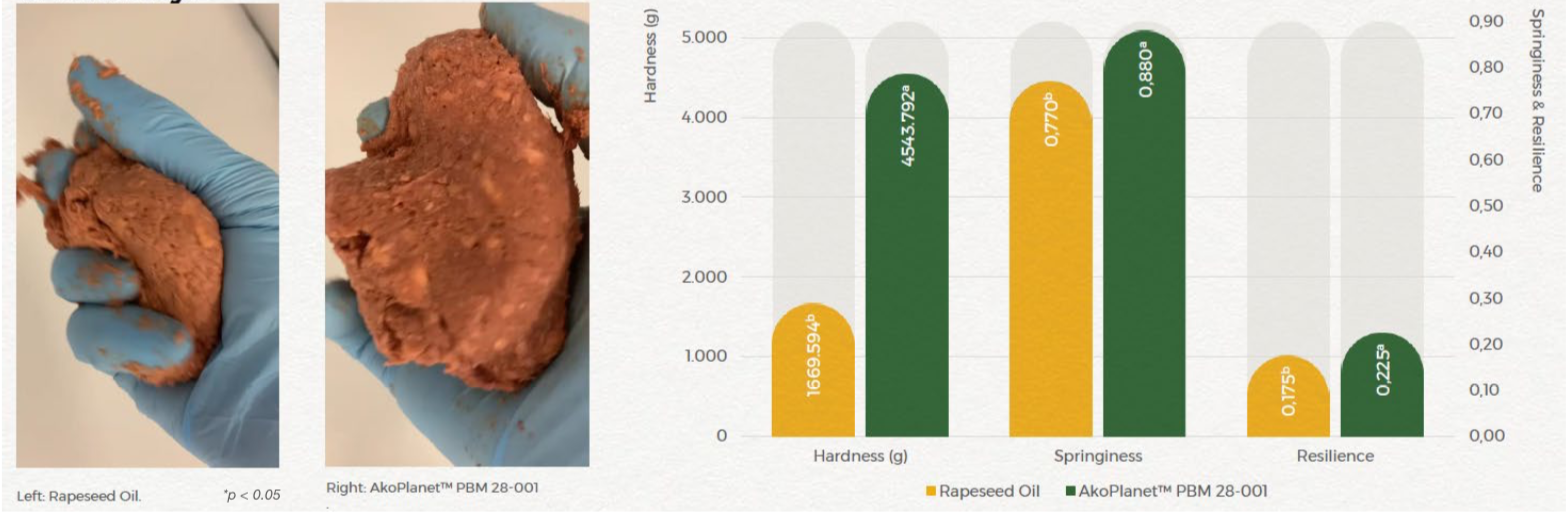

Texture profile analysis of raw patties made with AkoPlanet™ PBM 28-001 shows statistical differences in hardness, springness and resilience, aiding process efficiency.

Made with plant-based consumers in mind: the coconut oil in AkoPlanet™ PBM 28-001 is from our traceable primate-friendly supply chain.