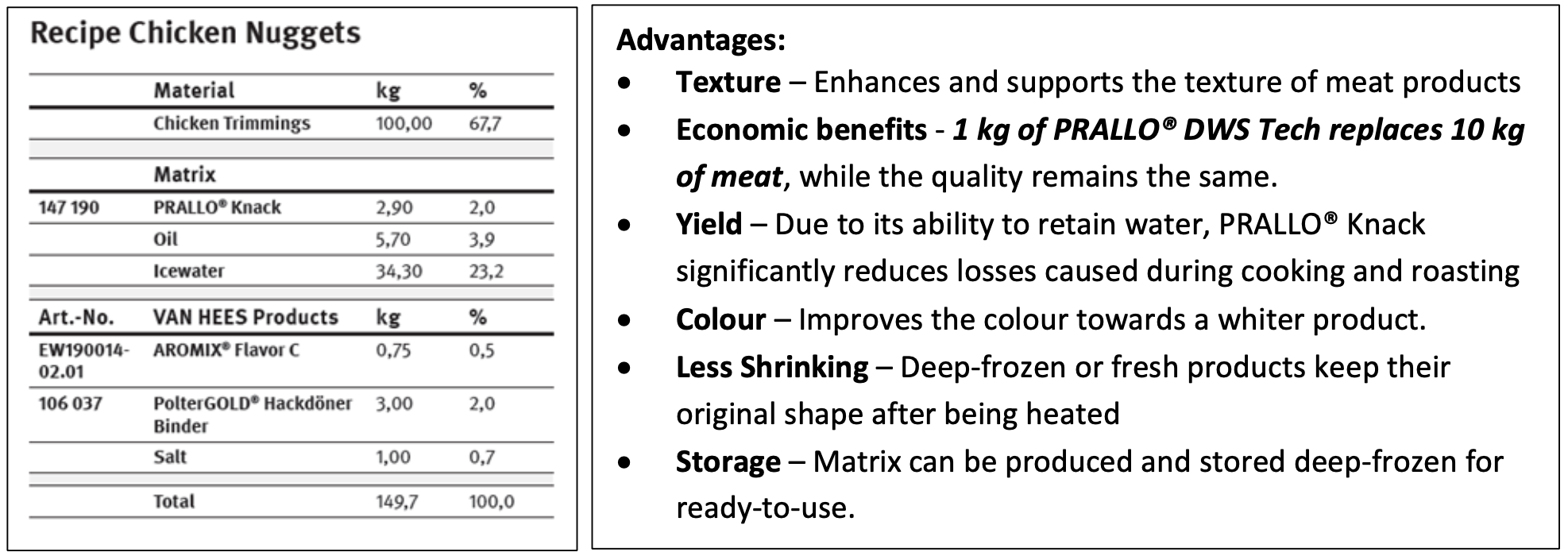

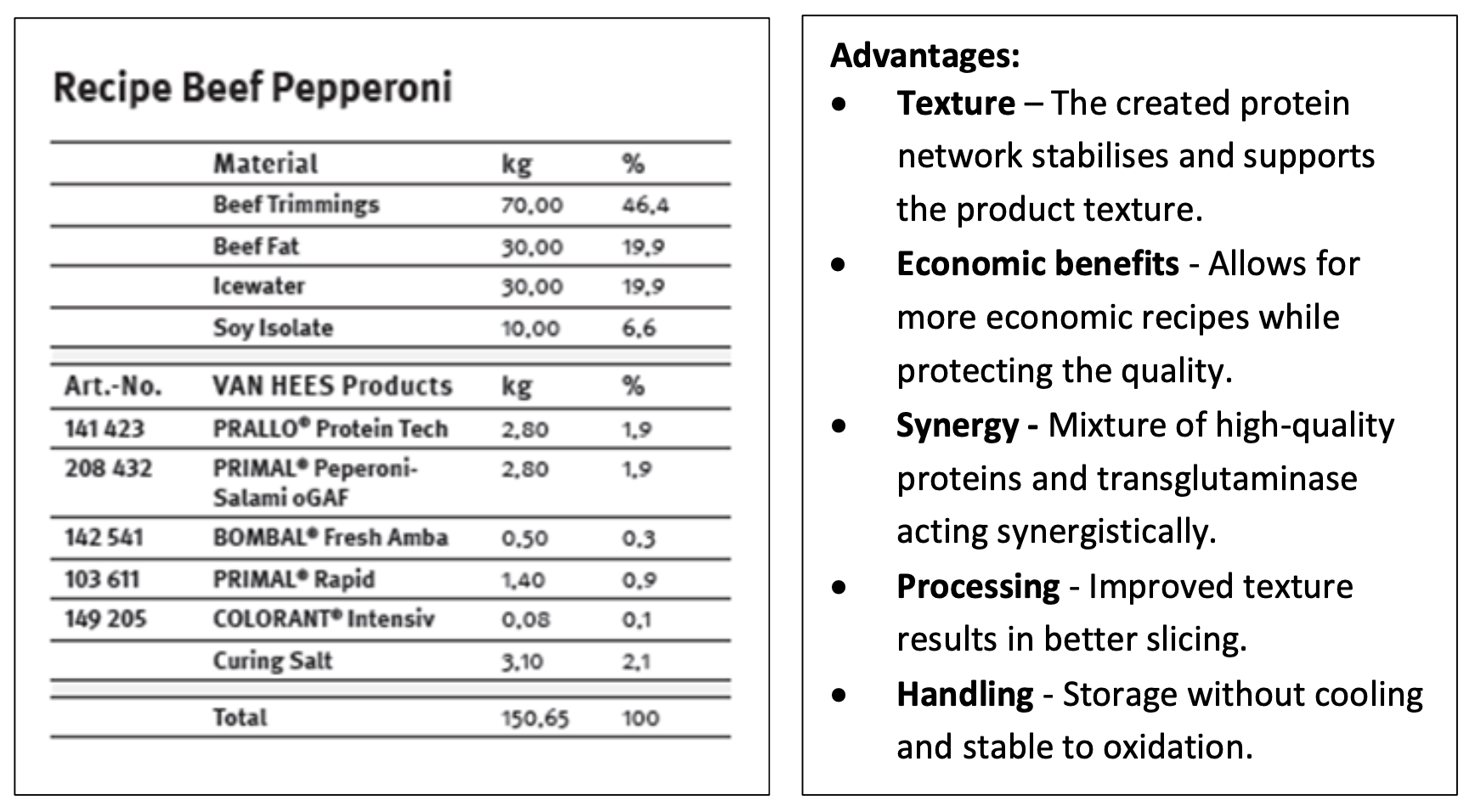

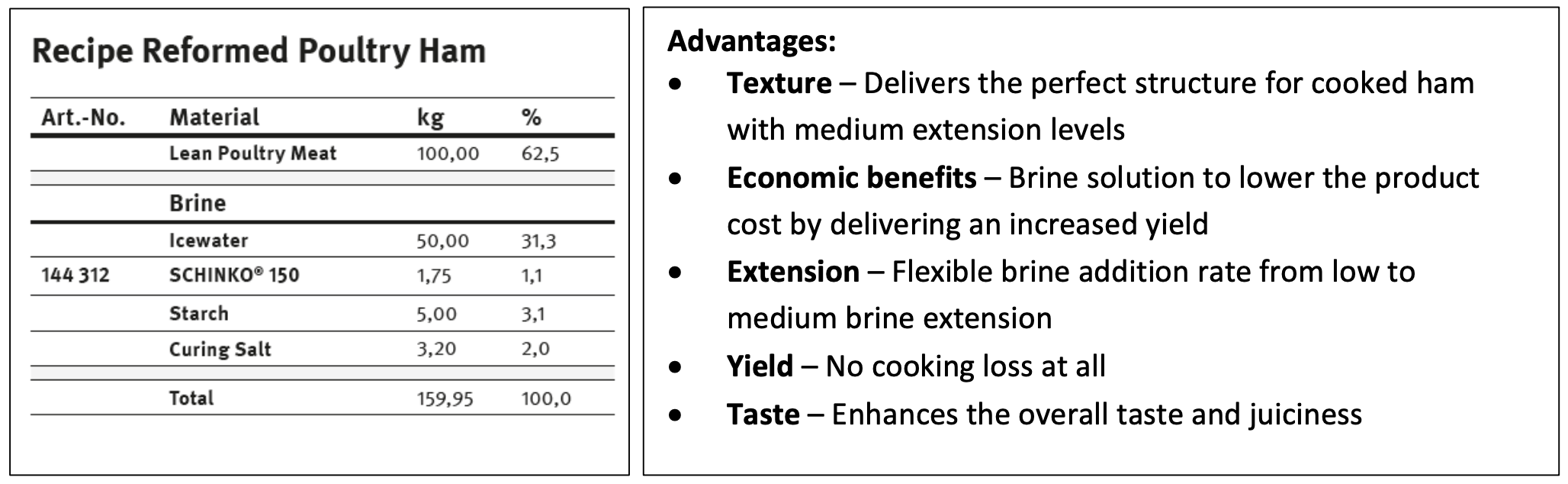

Animal protein solutions and applications which lower production costs and enhance the texture at the same time are important to manufacturers. With rising taxes and inflation across many countries, solutions and applications like these are essential to keep sales afloat. In this section, we will explore additive solutions specific to products like shawarma, nuggets, burgers and processed meats such as mortadella and pepperoni. The following solutions ensure juicy textures and enhance the protein volume, thereby reducing production costs.

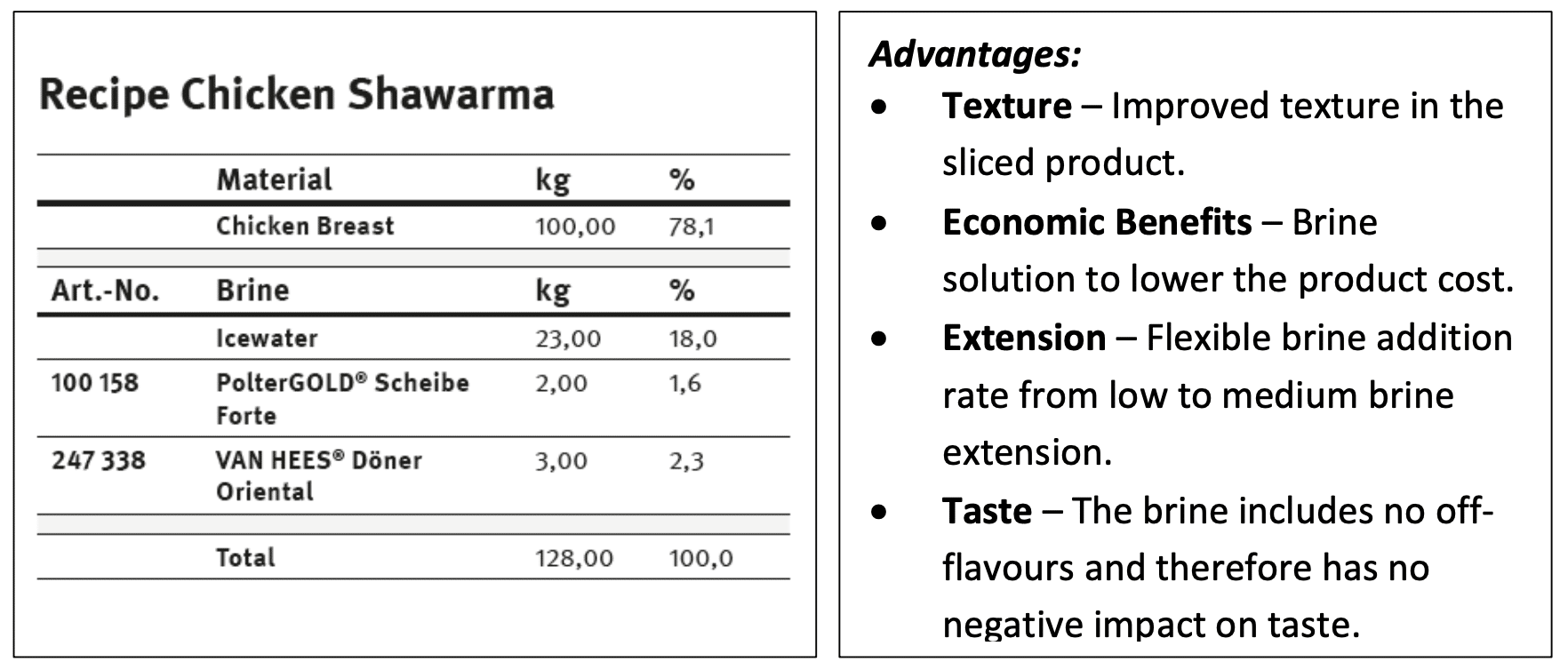

PolterGOLD® Scheibe Forte for Shawarma Production

PolterGOLD® Scheibe Forte is a brine additive for Shawarma and Döner products. It contributes to water binding capacity, texture, juiciness and binding between layers which will expand mass of the protein, thereby increasing the yield.