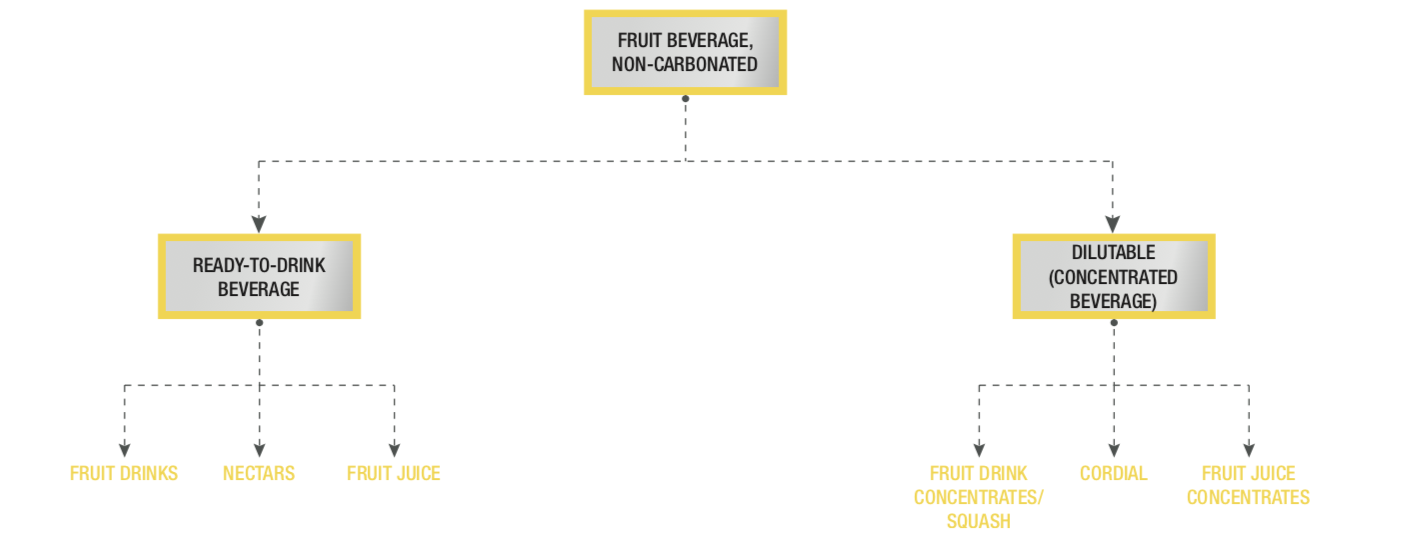

Different names are used for each variety within the fruit beverage range, many of which are used in specific geographical areas only. The figure below provides a guideline on the definitions of fruit beverages.

JU 543 – All-Around Stabiliser for Juices and Drinks

What is the Function of Stabilisers in Drinks?

The Benefits of Stabiliser Systems

Stabiliser systems are typically used in still drinks to:

- Suspend pulp and particles and avoid phase separation during storage

- Control mouthfeel and sensory properties

Introducing the Danisco Stabiliser: JU 543

Danisco has developed JU 543, an all-around stabiliser for almost all types of still drinks. The stabiliser can work in both juices and juice concentrates. The dosage of JU 543 is as low as 0.03% (may vary depending on fruit variety, required functionality and other parameters).

JU 543 helps in providing mouthfeel as well as stabilisation to the product to a great extent. JU 543 can be added to the juice processing line with the help of a high shear mixer and thus, no new infrastructural investment is required to use this product.

The main unique selling points of JU 543 drinks stabiliser are:

- Versatility

- Reliability

- Adaptability

JU 543 is a totally safe additive and meets all the specifications laid down by the WHO. It is a combination of cellulose gum and xanthan gum. The product is Halal-certified and can be added to all types of juices and drinks.

The unique effect of Danisco’s stabiliser systems is obtained by means of carefully selected raw materials, processing conditions and standardisation methods, ensuring products of high uniformity.

The benefits of using Danisco stabilisers in drinks are:

- Good suspending effect

- Effective sensory control

- Highly efficient and cost-effective

- Optimal selection and combination of ingredients

- Well-defined properties

- Wide range of specialised products

- Replacement of lost mouthfeel in low-calorie drinks

- Increased perception of higher juice content

- Addition of texture e.g. jelly drinks

Types of Still Drinks

The Use of Stabilisers to Improve the Mouthfeel of Fruit Beverages

Health and cost concerns have led to an increased interest in removing sugar from drinks and replacing it with a non-nutritive sweetener. Although sweeteners can replace taste loss, they do not replace the texture provided by sugar.

Danisco offers a range of juice stabilisers that can cost-effectively replace the loss of mouthfeel.

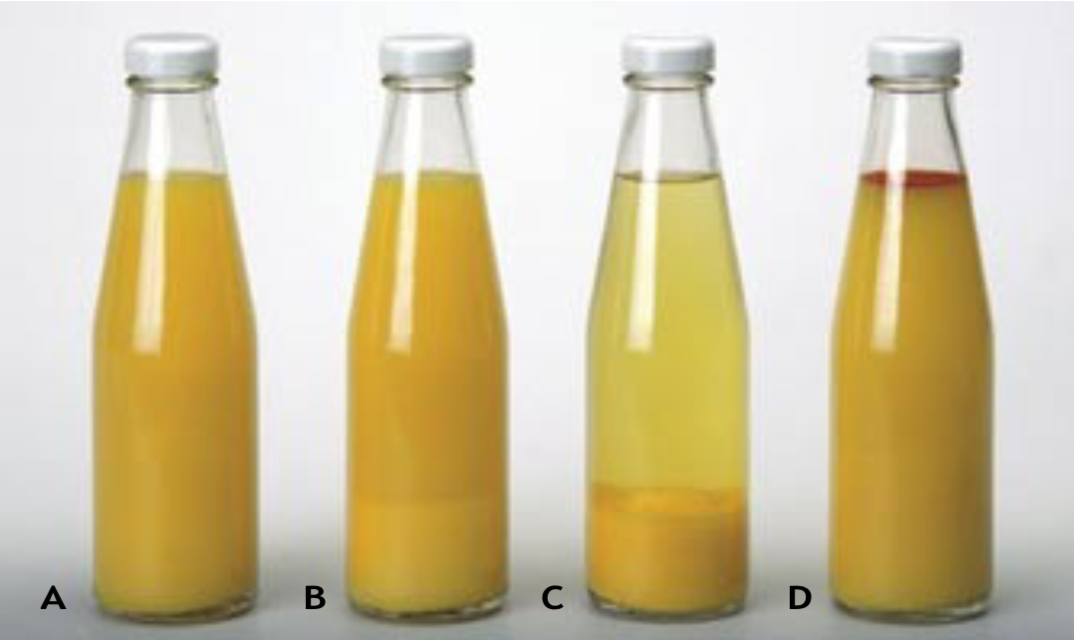

Types of separation in fruit beverages. A: stable beverage; B: slight sedimentation of pulp and fruit particles (ineffective stabiliser system); C: complete phase separation (wrong stabiliser system); D: Neck ringing – essential oil separation due to unstable flavor emulsion.

Fruit Pulp and Particle Suspension

The sedimentation of pulp, particle and cloud material is a phenomenon related to beverages based on a high content of fruit pulp solids. This takes place over a certain storage period and the result is a non-homogeneous product with an unattractive appearance. The most common types of separation in fruit beverages are shown in examples B and C in the figure above:

- sedimentation of pulp and fruit particles, and

- separation in a serum phase and cloud phase

The rate of separation is related to several factors such as the size and density of the particles as well as the viscosity and yield value properties of the beverage. A stabilisation and suspending effect are obtained using stabiliser systems with a high yield value. The presence of yield value is synonymous with the presence of a stabilising network in the beverage. Stabiliser systems give a high yield value and, thus, a good stabilising effect may not necessarily have high viscosity, as the two aspects are not related. This means a beverage may have a good suspending effect (high yield value) and low viscosity. In beverages requiring a high degree of flavor emulsion stability (see example D in figure above), the use of emulsifying agents may be necessary.

How to Select Stabiliser Systems for Fruit Beverages

When selecting stabiliser systems for fruit beverages, it is essential for the desired functional properties of the stabiliser system to be clearly defined and related to the type of beverage in question.

The most important parameters to define when selecting a fruit juice stabiliser are:

- the type of beverage – ready-to-drink or dilutable

- the level of pulp-suspending effect required

- the mouthfeel characteristics – heavy or light

- the viscosity profile

- the fruit type

- the fruit juice/concentrate content

- the required flavor release

- legislation

- cost