Confectionery Fats: CBS, CBR and CBE

When today’s consumers indulge, they want every bite to be pure perfection and are also on the lookout for healthier options too. That’s why we deliver the best solutions to help you create silky smooth, delightfully delicious confections which fulfil the highest expectations.

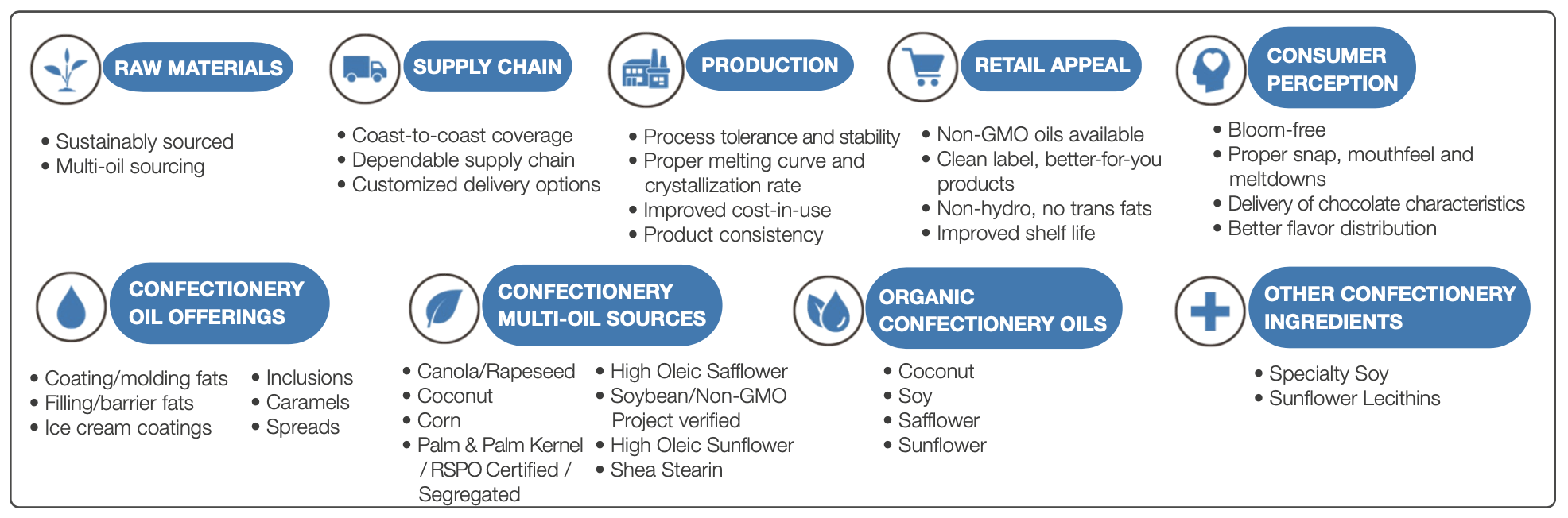

We help you deliver pure confectionery perfection, with our extensive portfolio of plant-based, multi-sourced cocoa butter alternatives and filling fats.

AAK practices sustainable sourcing in their all their key raw materials, including the shea, palm and palm kernel oil used in our specialty chocolate and confectionery fats. The sustainability approach is embedded in all parts of their value chain, from the crop all the way to the brand on the store shelf.