With consumers eating more frequently at home the demands for fresh baked goods which can be stored in the freezer and quickly prepared in the oven have been growing since the start of the pandemic. But these consumers are not only seeking the convenience of a freezer to oven solution but also the fresh taste, light texture and nostalgic joys of a croissant or pastry.

Under FSL’s partnership with IFF, we are offering the Grindsted POWERFreeze 406 bakery improver solution to address these needs of manufacturers and discerning consumers.

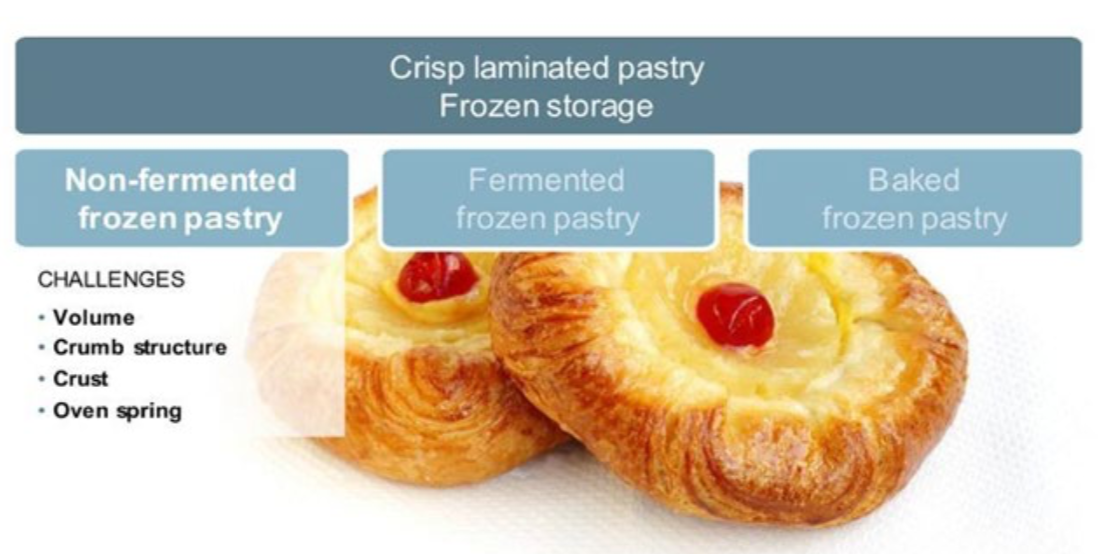

Introduction to Freezer to Oven Solutions

Freezer to Oven (FTO) solutions are non-proofed / fermented frozen pastries which require no thawing and no proofing. The products are simply trayed up straight from the freezer and baked in the oven. Hence in less than 30 minutes these pastries are ready to be sold – making them the ideal solution for coffee shops, petrol stations and individual consumers at home.